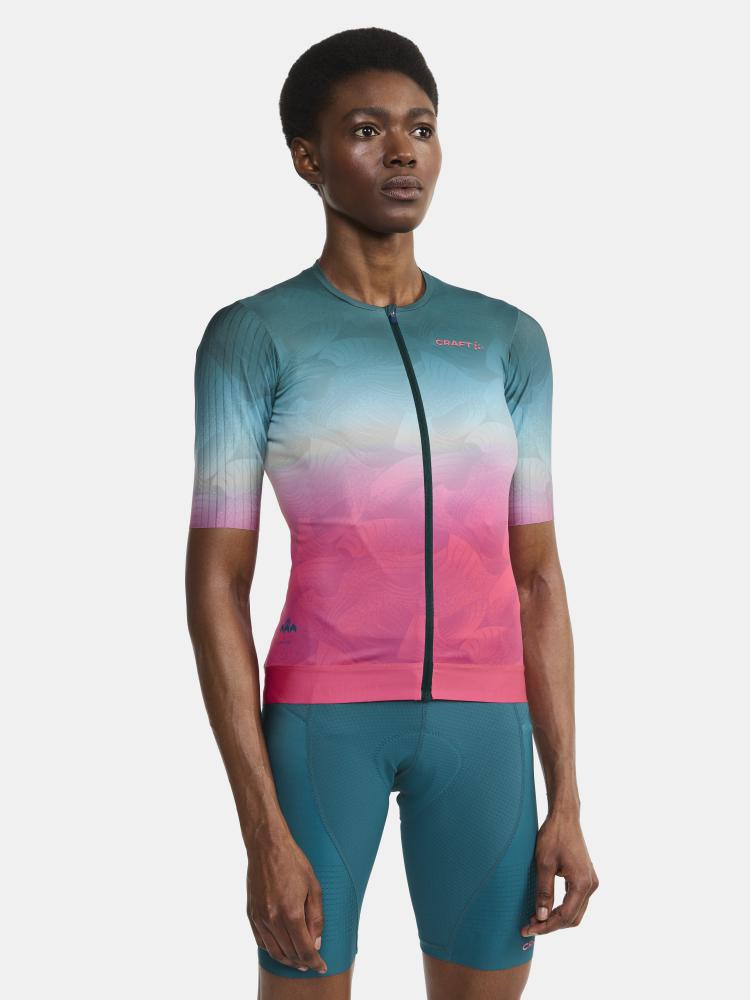

03 MATERIALS

REUSE TO REDUCE

Turning five empty soda bottles into a t-shirt isn’t just a clever trick. It’s also a great way of reducing our dependency on petroleum and helping the world turn the tide on plastic waste. Today, it’s estimated that 8 million tons of plastic end up in our oceans every year. A mere 10% of the global plastic waste is recycled and put to use again.

Thommy Bäcklin, Head of Product

KPI's

All products fully or partially made from more preferred fibres by 2025

All garments made from more preferred materials and more sustainable production methods by 2027

Joint strategy plans with suppliers for responsible water and chemical management by 2024

Ongoing evaluation of new technologies and innovative fabrics

”Recycled polyester generates 79% less carbon emissions compared to virgin polyester.”

That’s why we’ve taken sight of an important milestone going forward. To reach our long-term objective of reducing emissions by 50%, we will continue to evaluate and select materials with a lower carbon footprint.

In the textile world, chemicals are a necessary part of the production chain. Our overall goal is to prevent the use of harmful chemicals in our supply chain. To stop hazardous chemicals from entering our production process, we have created a Restricted Substance List, designed in accordance with legislation such as REACH (European Union chemical legislation) and other industry standards. The list prohibits the use of dangerous and unnecessary chemicals in the production of Craft garments, and is mandatory for all our suppliers to follow. For the same purpose, we also have an active partnership with RISE Chemical Group, sharing knowledge and findings with the organization’s members.

Preferred Materials

RECYCLED POLYESTER

Made from used PET bottles, recycled polyester is a strong, durable fibre with a much smaller ecological footprint than virgin polyester. By using recycled polyester, it’s estimated that 70% less energy is needed in the production process. Sourcing recycled rather than virgin polyester also decrease the fabric’s carbon emissions with 70%.

SOLUTION DYE

A coloring method where the dye is fused with the synthetic fibre rather than added to the finished fabric. Solution dye requires 75% less water in the production process and reduces energy consumption and carbon emissions by 30%. By adding the color granules to the liquid polymer solution, there is no need for additional dyeing, rinsing and drying. The result is a colorfast, UV-resistant fabric that won’t stain or bleed.

SEAQUAL MARINE PLASTIC

A sustainable, fully-traceable raw material made from marine litter, such as end-of-life fishing nets and other plastics used in aquaculture. SeaQual Initiative is a community of individuals, organizations and companies working together to clean our oceans. The plastic collected from oceans, lakes and rivers are sorted by polymer type. The different plastics are then upcycled by shredding them into pellets or chips, that can be remade into yarns and molded shapes.

COTTON

A plant-based, renewable fibre that can be recycled or biodegraded at the end of the product’s lifecycle. The cotton fibre is harvested, combed and spun into a yarn that can be used to create an all-cotton fabric or mixed with other fibers to create durable blends.

WOOL

A natural, renewable fibre made from the coats of sheep, goats and similar livestock. Our goal for 2025 is that all wool used in our garments is produced in accordance with the Responsible Wool Standard (RSW), a global program focused on promoting environmental sustainability and animal welfare in the wool industry.

BIOBASED

A material made from living organisms such as non-edible plants or other renewable agricultural, marine, and forestry materials. Examples of biobased materials include cellulose, castor beans, corn, soy and vegetable oil.